Predictive services

Initial situation

With the help of data from continuous monitoring of machine tools, the company TRUMPF GmbH promises to

Co. KG (hereinafter referred to as TRUMPF) to detect faults at an early stage and thus avoid machine downtime. TRUMPF plans to offer its customers early detection of faults as a predictive service. The feasibility of a predictive service for laser cutting heads was to be examined in the quick check. The performance of this can

e.g. by dust particles, which can be triggered by various events.

Solution idea

Methods from the field of machine learning are used to detect possible impairments and errors in the cutting process at an early stage. Various Trumpf data sources were used for this purpose, in particular log files and service reports, which are also available later directly on the machine.

Benefit

With the help of the Predictive Service, a failure of the laser cutting head of the machine tool can be detected at an early stage. With a reliable prediction, the service can

customers, e.g. as a monitoring solution. On the one hand, this prevents machine downtimes. It also reduces the number of service calls for TRUMPF technicians.

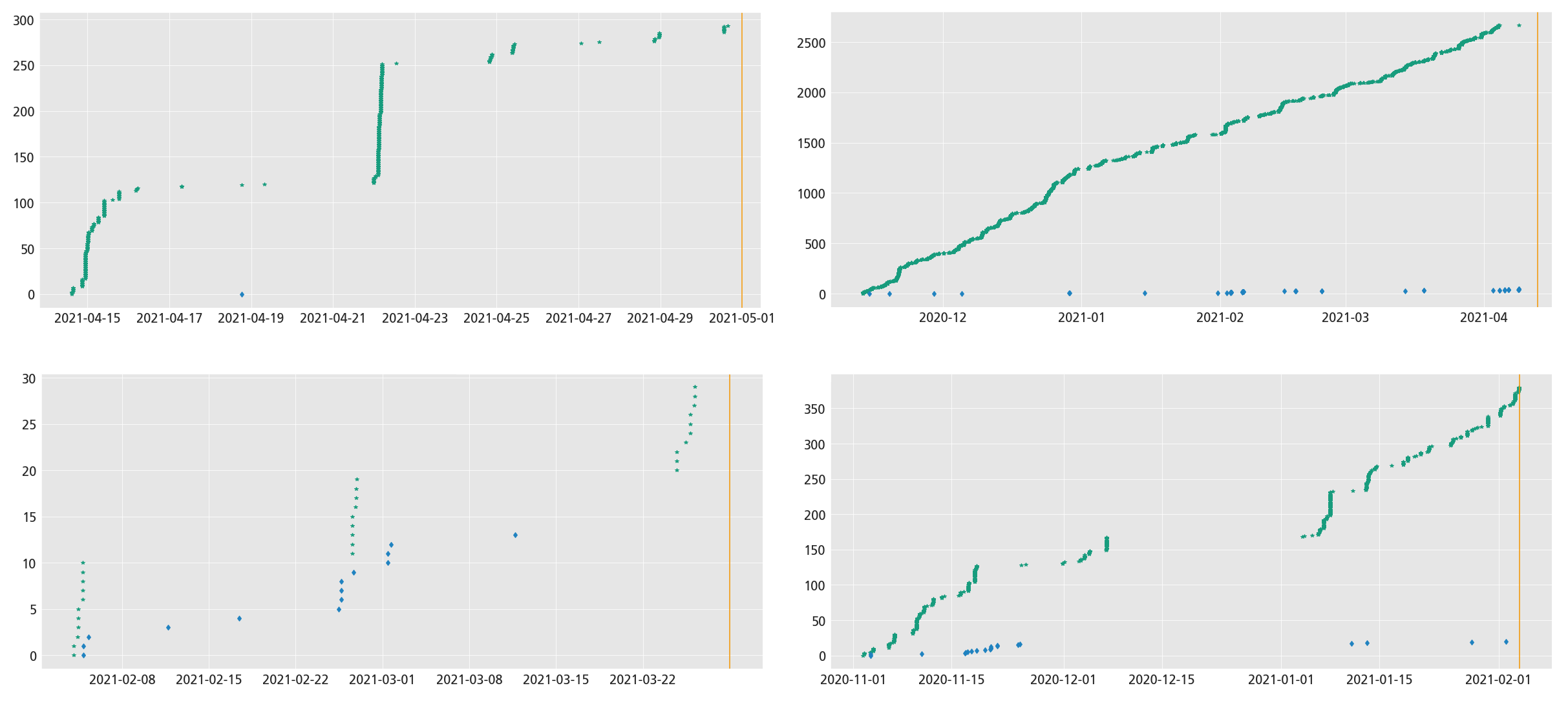

Implementation of the AI application

Trumpf supplied data from various sources, which was merged into a large data set. Using various parameters, an attempt was to be made to predict the remaining runtime until the error message using methods from the field of supervised learning. During the data preparation required for this, however, it turned out that the events that occurred before an error were very different (see Figure 1). For this reason, the feasibility of the predictive service for the use case could not be confirmed during the quick check with the available data.