High speed picking

Initial situation

robomotion develops production and packaging machines that have to handle a large number of different products in a targeted manner. The picking systems are programmed individually for each product to be handled. Object and position recognition in particular requires programming by an expert who selects suitable image features for recognition.

However, due to smaller batch sizes and increasing product diversity and flexibility requirements, reprogramming for each new product is not always economical.

Solution idea

The programming of the object and position recognition software is now to be automated using machine learning methods, whereby only very little sample data is available for training.

In addition, object recognition should also be able to differentiate between several product types in mixed systems and make it possible to add further new products without a great deal of training. It must therefore be able to learn the appropriate detection features for different products itself.

Benefit

A faster and more economical conversion of systems to other or new products is possible if the (manual) effort required to collect data and the (time) required to train a machine learning process for object recognition remain manageable. A solution of this kind makes it possible to convert packaging and production machines to other products much more quickly and thus improve capacity utilization. It also reduces or completely eliminates the need for cost-intensive manual adjustments by experts.

Implementation of the AI application

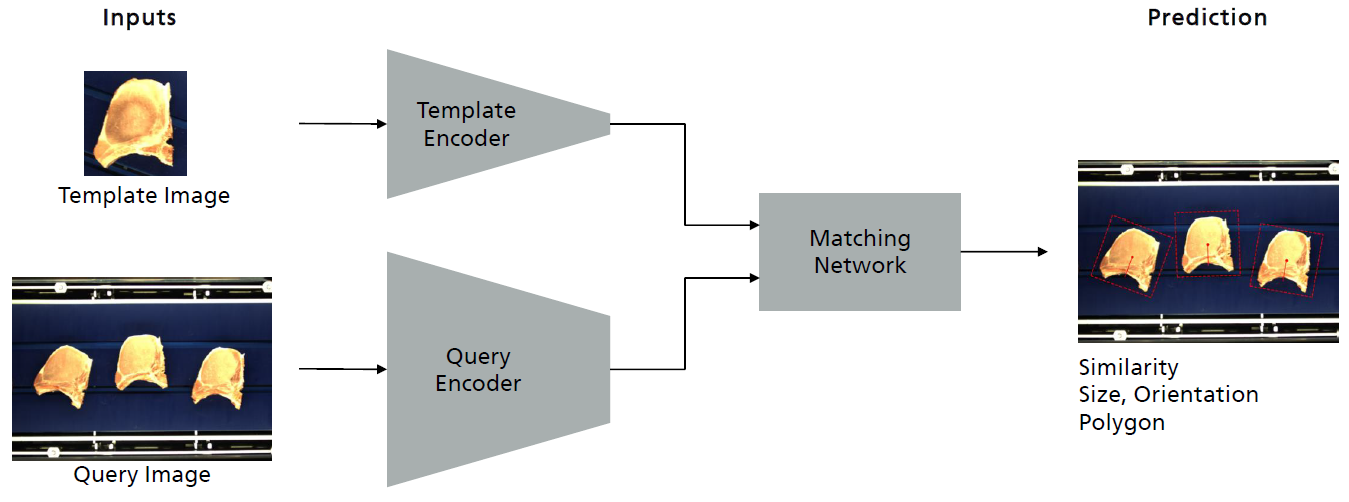

As part of this project, a CNN model was trained using publicly available images and without manual annotations, which made it possible to detect an object depicted in a scene on the basis of a reference image (template). This demonstrated that the chosen approach of similarity-based learning is not only suitable for predicting correlated features, but also for regression-oriented bounding boxes.

The results of the project will now serve as the basis for developing the described approach into a solution for productive use.