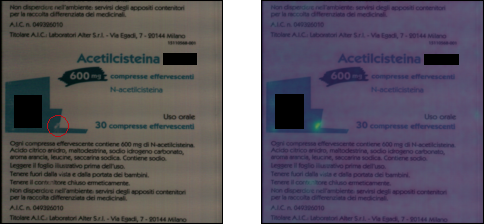

AI-based print image control for effervescent tablet tubes at Jaco

Initial situation

Jaco Dr. Jaeniche GmbH & Co. KG is the European market leader for effervescent tablet tubes and produces over 300 million printed articles annually with a total reject rate of less than 5 percent. As a manufacturer of primary packaging for the pharmaceutical and food sectors, the highest quality requirements apply. The print image was checked manually on eight out of nine printing presses by means of spot checks. A camera system already existed on one machine, but its high sensitivity led to increased pseudo errors and unnecessarily high reject rates. The challenge was to distinguish real printing errors from system-related false alarms in order to enable a comprehensive automated 100 percent inspection without excessive waste. Existing systems could not differentiate between actual quality defects and technically induced pseudo-errors. This prevented fully automated implementation and continued to require manual monitoring.

Solution idea

Development of AI-based anomaly detection to intelligently distinguish between real print defects and pseudo defects. The solution includes multi-stage image pre-processing with line offset correction and robust template matching to precisely position the inspection windows. The AI model is trained exclusively on error-free reference images and uses memory bank technology for compressed storage of relevant image properties. This anomaly detection identifies deviations from the norm, enabling reliable automated print image inspection without excessive reject rates.

Benefit

The project shows that 100 percent control of all print images without excessive reject rates is possible with a combination of rule-based image pre-processing and AI-based methods for anomaly detection. Reducing the pseudo error rate by an average of 85.7 percent has the potential for significant efficiency gains and cost savings. Reliable automated monitoring relieves the burden on personnel, enabling more machines to be operated and counteracting the shortage of skilled workers. This leads to a competitive advantage through the highest product quality with optimized production costs.

Implementation of the AI application

The solution was technically implemented as follows: Firstly, through a two-stage rule-based image pre-processing with a correction of the line offset caused by the image acquisition; and secondly, through template matching using a master image to counteract a possible offset during image acquisition during unwinding and thus correct the position of the measurement window. The anomaly detection was trained on 50 error-free reference images and evaluated on error and pseudo error images provided by Jaco. The described procedure was tested on 6 different print images, whereby the pseudo error rate could be reduced by 85.7 percent on average.

The technology enables continuous improvement by integrating new data into the training data set. For Jaco, as the European market leader, this represents an important technological advance in supplying large contract manufacturers in the regulated pharmaceutical and food sectors.