Automated testing of fasteners during production

Initial situation

ARNOLD faces the challenge of optimizing quality assurance in production due to increasingly complex products. The previous random checks on 400 machines at two locations are becoming increasingly complex as a result. These checks, which are carried out at regular intervals, include complex measurements such as roughness and shape tolerances, which are made more difficult by factors such as oil contamination and high part temperatures (up to 300°C).

A core problem is the lack of integration of the inspection system with the ERP system, which leads to information deficits. The current processes require manual intervention in the event of non-compliant inspection results and do not provide sufficient support for the immediate documentation and analysis of data. This limits productivity and makes it difficult to achieve strategic goals such as zero defects and complete digitalization.

Solution idea

The project involved the implementation of an automated inspection system with a robot and an automated, image-based inspection solution. Integration into the ERP system enables automated documentation and alerts in the event of deviations, so that a quick response is possible. The aim of the solution is to minimize the inspection effort for personnel and make quality control more efficient.

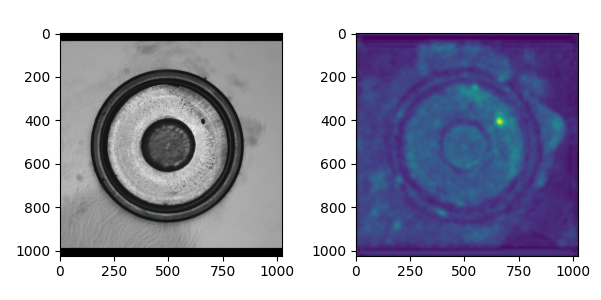

As part of the project, the possibility of an automated, image-based inspection at the points defined in the inspection plans was investigated.

Benefit

The introduction of automated image-based inspection offers numerous advantages. Firstly, it enables continuous and accurate monitoring of production, which reduces human error. Secondly, the automated recording and documentation of inspection results contributes to the pursuit of the zero-defect target and supports real-time trend analysis. This data makes it possible to proactively adjust production processes and thus improve the quality of the end products. Thirdly, the efficient inspection methodology increases productivity by reducing the inspection effort per system and hour. Overall, image-based inspection contributes significantly to the digitalization and automation of production processes and makes a decisive contribution to strategic target tracking and quality improvement in the mass production of small parts.

Implementation of the AI application

As part of the project, various small parts were evaluated in terms of their automated inspectability using image processing. The detailed analysis of the inspection plans led to an assessment of the inspectability with standard camera systems and shape-from-shading systems. The image evaluation included analytical dimensional accuracy checks and AI-based anomaly detection, in particular using patch-based algorithms trained on good parts. This made it possible to efficiently identify bad parts. Despite limited sample images, AI-based anomaly detection showed promising results for precise evaluation.