Position-invariant classification of teeth

Initial situation

VITA Zahnfabrik produces several million prefabricated teeth with different tooth geometries for dental prostheses every year. Due to the nature of the process, the teeth are not produced in a single variety, but different tooth types are mixed together. After production, the teeth are stored as bulk material in containers that contain many different tooth geometries. For sale, the teeth must be separated and sorted according to their geometry. To this day, sorting is done manually or rarely with the help of a classic image processing system. However, the latter is not sufficiently reliable and can only be used if only clearly different tooth geometries are present. As part of the Quick Check, an AI-based optical recognition system was to be investigated in order to sort the different, sometimes very similar teeth automatically and very accurately.

Solution idea

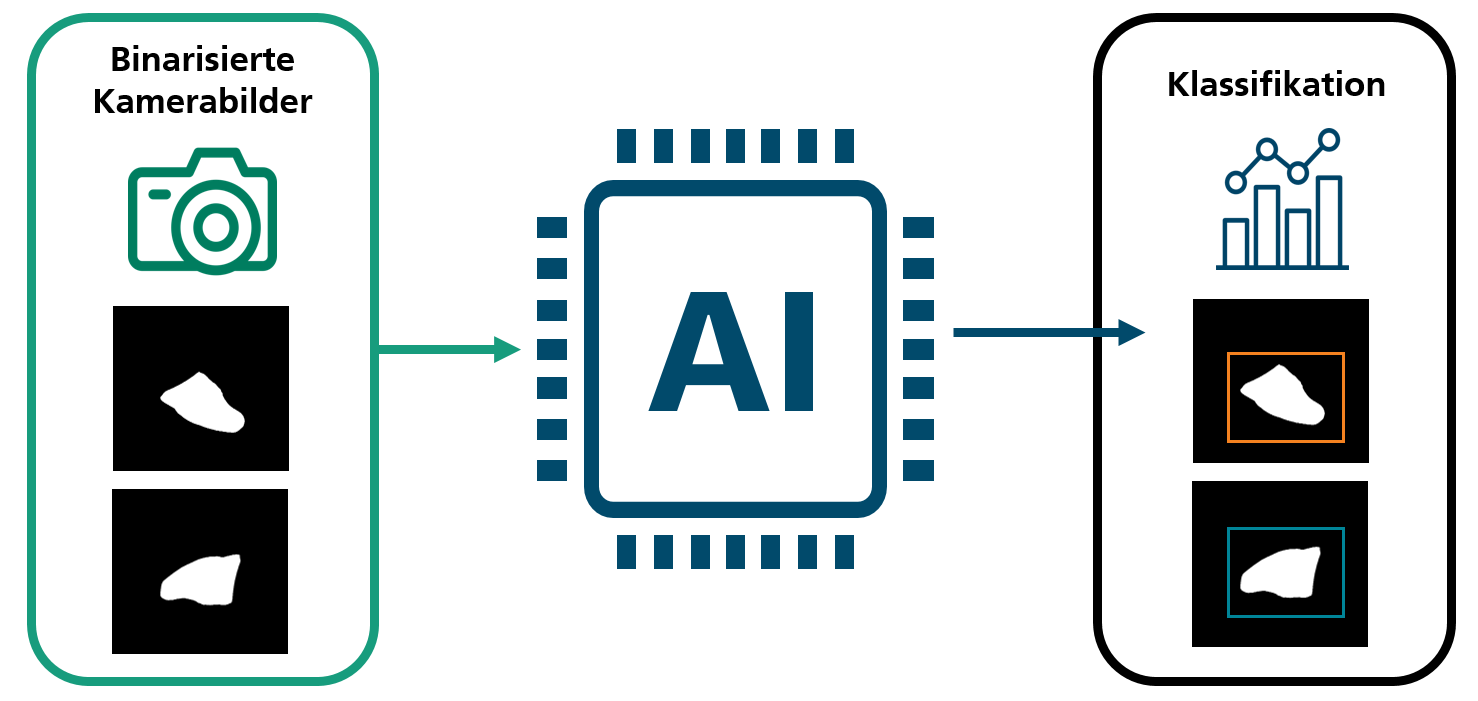

An AI-based approach will be used for this purpose. Unlike rule-based image processing algorithms for classification, the distinguishing features are not selected manually, but are learned automatically during model training. The necessary training data set is built up by taking images of the teeth in different orientations. Teeth of a known type are separated for this purpose. The trained AI model is then used to assign unknown teeth to the correct geometry type. As the teeth also occur in different colour variants, the images are first binarized. In this way, the AI model distinguishes independently of the tooth color and only depending on the geometry of the tooth.

Benefit

This automated tooth classification has advantages that can have a positive effect on productivity at VITA Zahnfabrik. First of all, the manpower required to manually sort the teeth is reduced. In addition, the time-consuming pre-sorting of teeth, which was necessary for the existing sorting system, is no longer necessary. This saves time and increases efficiency, which in turn counteracts the labor shortage and can make production more resilient. Furthermore, the project increases sorting accuracy and re-sorting is less time-consuming. Overall, the project can significantly reduce costs, which helps to secure the company's future.

Implementation of the AI application

A neural network for object recognition was used for the AI-based sorting. Due to the mechanical feeding of the visual inspection setup, only one tooth at a time is in the camera's field of view. However, the teeth are not brought into a defined position, but can be in any object position. In order to implement a robust sorting system, an automated data acquisition system was set up in which the teeth can be recorded in different positions without manual effort. This results in a large training data set that also represents rare object positions. Secondly, the images were rotated during training. This means that rotations around the Z-axis of the camera can be simulated automatically and the resulting network is invariant to this rotation of the teeth.

The Quick Check examined 28 different tooth geometries with a high potential for confusion. These tooth types can be classified 99.6 percent correctly on unseen test data. The sorting accuracy achieved thus clearly meets the requirements set by VITA Zahnfabrik for an automated tooth recognition system.