Damage evaluation with machine learning

Initial situation

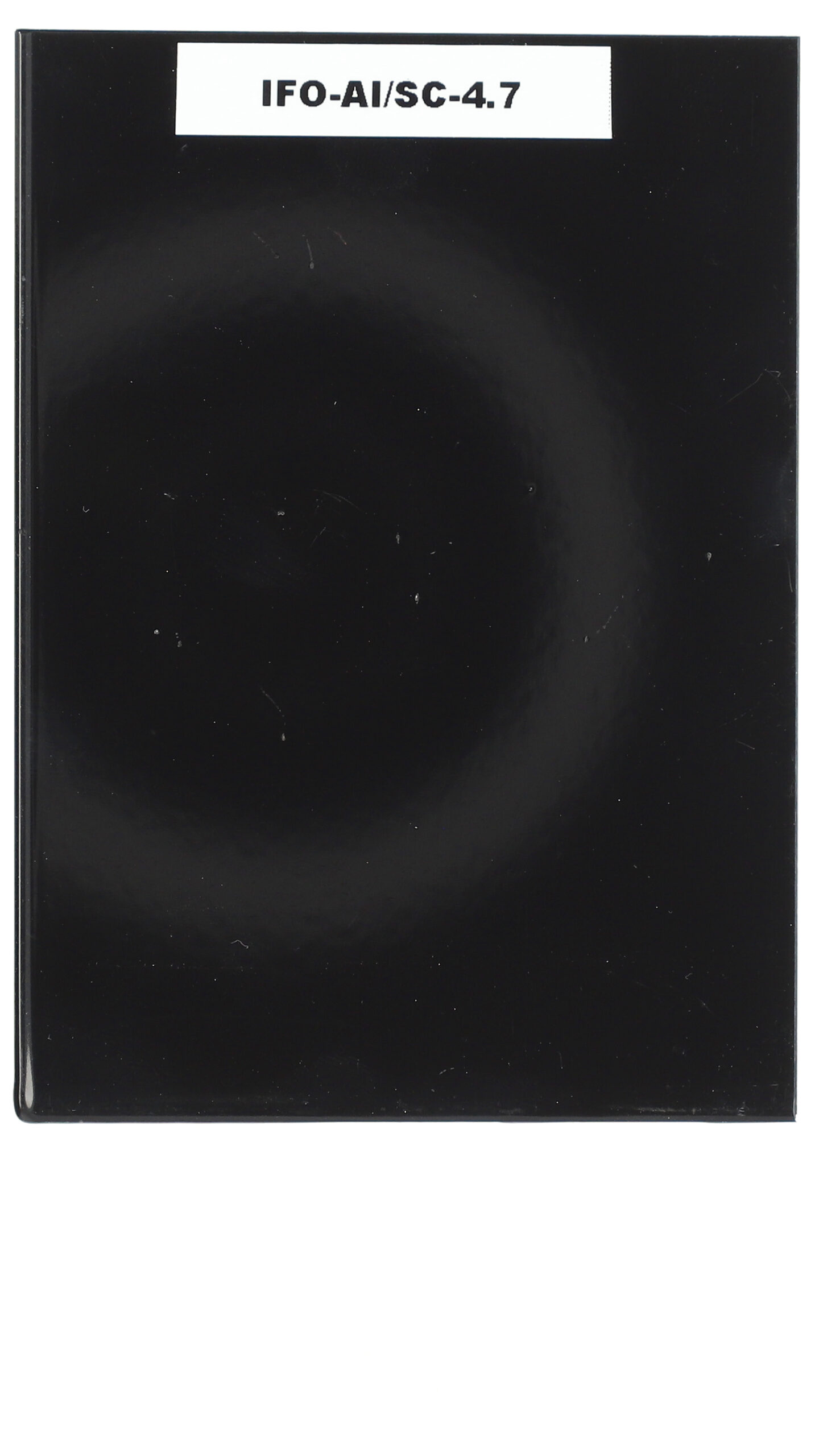

The underbody area of cars is exposed to heavy mechanical and corrosive loads. Stones and gravel on the road can penetrate the corrosion protection, leading to premature corrosion and possible failure of important parts. To protect against this risk, stone chip protection coatings are used, which must be tested for their suitability. For this purpose, sharp-edged steel shot is fired at the samples in the laboratory using compressed air. The resulting damage pattern can now be assessed either visually using comparison images, by manual counting or using expensive special equipment. This makes the evaluation either very cost-intensive, time-consuming or inaccurate. If normal photos can serve as the basis for an evaluation that is supported by image recognition and machine learning, a much more differentiated assessment of quantity and quality can be made than has been possible to date. Due to the complexity of the resulting damage patterns, the use of AI methods for photo evaluation is necessary. In addition, the evaluation is faster and, in principle, also possible from a distance.

Solution idea

This quick check uses an object detector to detect almost all types of damage patterns. The object detector makes it possible to count the number of defects on the surface and determine the location of the defects. This information can also be used to calculate the size of the damage by calibrating the images. The damage patterns are generated by laboratory tests in which sharp-edged steel shot is subjected to compressed air of varying intensity. In order to train the object detector, prior annotation in the form of bounding boxes of the surface defects is required.

Benefit

Implementation of the AI application

One of the well-known architectures for object recognition called YOLO was selected as the basis for the ML model. The object detector divides images into a grid system. Object detection is performed for each cell of the grid. The object detector is trained using 41 manually annotated images. Additional pre-processing of the data is required to solve the problem of data scarcity. The object detector achieves a mean average accuracy of about 0.85 with an overlap of at least 50%.