Digital integration

Initial situation

Veeser Plastic-Werke GmbH has a very good reject rate, adherence to delivery dates and complaint rate. The Overall Equipment Effectiveness (OEE) is to be increased in the medium term. This is to be achieved through the use of AI solutions. While basic isolated data sources are already available, they have not yet been comprehensively evaluated and used for process optimization. The AI Explorer aims to develop AI solutions for the targeted use of available data.

Solution idea

Two main proposed solutions were discussed as part of the AI Explorer:

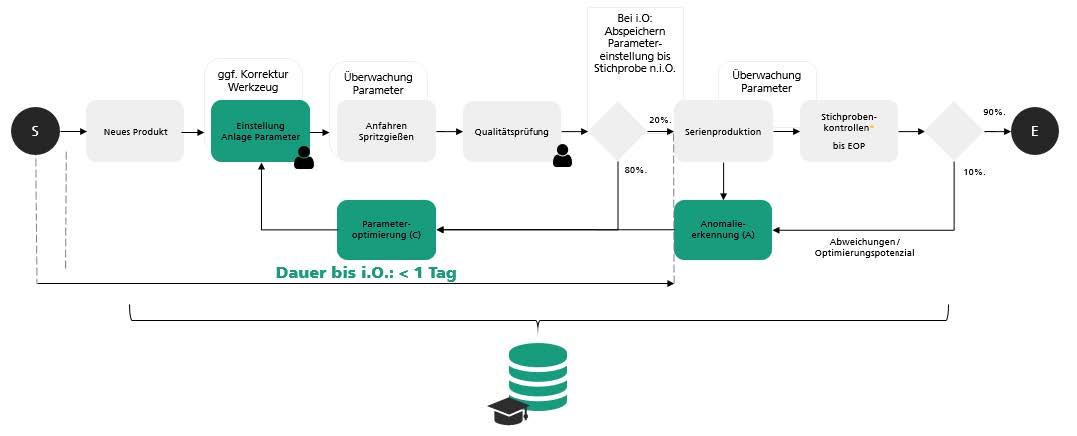

A) The gradual creation of a linked knowledge database for the injection molding process and the integration of previously isolated data sources. The use of an anomaly detection system should serve as an early warning system for deviations. In addition, learning more robust injection molding parameters based on the database is a possible solution.

B) Learning optimal system parameters for new products is another solution idea in the course of industrialization. The reinforcement learning approach can be used on the basis of simulated filling studies and a digital twin.

Benefit

A) On the one hand, the benefit lies in the knowledge generation that results from the networked database. In addition, the database forms the basis for further AI applications such as anomaly detection (increasing responsiveness) and parameter optimization (increasing process robustness).

B) The benefit consists on the one hand in the expansion of process knowledge and on the other hand in the reduction of personnel costs per year for carrying out the filling studies, and

initial adjustment of the injection molding systems. For customers, deepening their process knowledge is the primary potential benefit.

Implementation of the AI application

A) After the data connection and provision, the anomaly detection for the process parameters of the injection molding system should be integrated. An individual model may have to be created and implemented for this purpose. The more complex solutions for parameter optimization are then implemented.

B) Implementation takes place in three steps:

- Provision of historical data and an interface to the simulation software

- Implementation and pre-training of the AI agent (supervised learning)

- Application in a productive environment and follow-up training (RL)