AI-ready machining

Interfaces and protocols

In industry and mechanical engineering in particular, the application of artificial intelligence often fails due to the provision of high-resolution relevant data that makes it possible to describe the process with sufficient accuracy. The deficits often consist of a lack of sensor technology or missing interfaces to transfer the data to a utilization point for higher-level data analysis. The computing power within the machine is primarily used to control and calculate the motion sequences, meaning that there is no computing capacity available for additional applications such as AI inference.

However, the quantity and quality of the data is of fundamental importance for the use of AI for process monitoring and active process interventions within the production process. The information from different subsystems such as machine and external sensor data, if available, is transmitted via proprietary and/or interoperable interfaces within the processing machine and can also be communicated externally in this way. The data is usually available as time series in various formats with different sampling rates, some of which depend on the components installed. The machines themselves do not store the sensor data in the long term and only use it for individual monitoring purposes, such as spindle temperature or fill levels.

The transmission to the outside depends on the selected or available interface standard. The different standards and interface types as well as the individual transmission performance are problematic here. Transmission errors or packet losses also frequently occur, meaning that a recording is incomplete. The standards are not capable of complete transmission of all data generated within a processing machine and by external sensors.

Technology comparison

Various interfaces and transfer standards are available on the market. Some of these standards are marketed as proprietary interfaces, while other solutions operate as platform-independent, cross-platform alternatives. In the technology comparison, the existing interfaces such as OPC-UA, MTConnect, etc. and transmission variants such as MQTT, CoAP, etc. are examined and compared. The aim of this comparison is to establish the compatibility of the interface and transmission standard and to assess the technological limits in terms of transmission rate and other parameters. Compatibility is also evaluated with regard to signal and control type. The result is a usable overview with information on compatible standards and transmission performance.

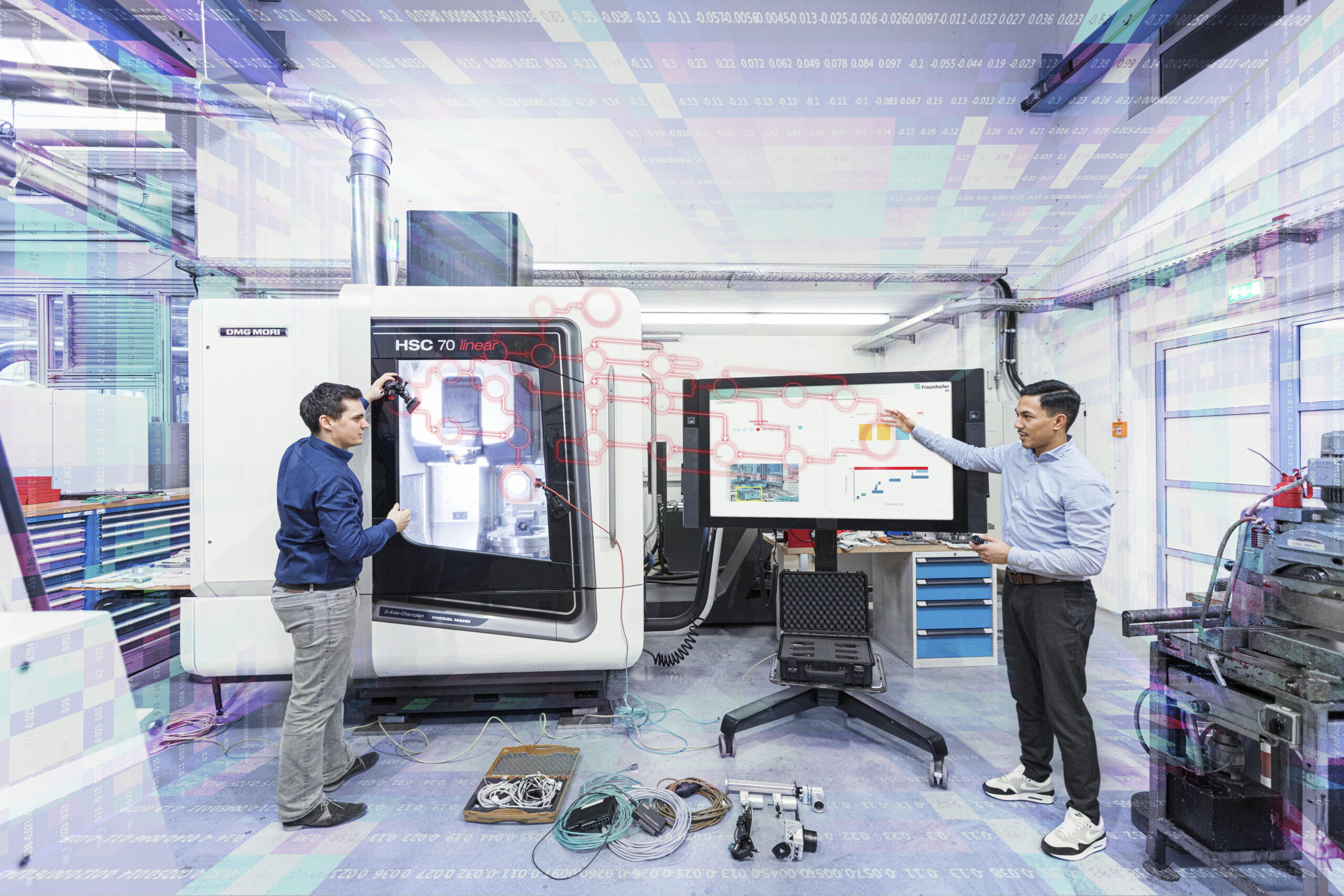

Demonstrator machine

Based on the results of the technology comparison on the given compatibility between interface and transmission standard, a practice-oriented benchmark test is developed, which can be used to dynamically test the performance of the combined interfaces and transmission standards. In addition to the internally available machine data, e.g. axis position or performance parameters from the NC or PLC, external sensors are also integrated. The defined test sequence should therefore enable a comparison between protocols and interfaces as well as protocol to interface with regard to the achievable performance measured against defined KPIs. For this purpose, a representative selection of interfaces and edge devices from the previous technology comparison will be integrated into a demonstrator system and experimentally examined using the defined processing sequence. The result is a comparison of the theoretically possible transmission performance under operating conditions and the influence of interferences such as electromagnetic interference in a practical process. This gives future users a quick overview of possible integration options and an assessment of potential interference factors in the selected transmission paths and communication interfaces.

AI-based synchronization

The last part of the project aims to achieve AI-based synchronization of the data. A neural network is to be trained from the existing knowledge about interfaces and protocols, which synchronizes the data based on the input data in terms of time and frequency, summarizes and continuously stores it and, when transmission errors are detected, informs the end user of the fault in the data. This adaptive control of the data streams should make it easy to add new sensors and/or interfaces to existing systems and enable central data storage for the use of AI in the production process.

Target group

The "AI-ready machining" project is open to all business partners who are interested in using AI in the process monitoring or control of their systems. By taking an interdisciplinary approach to the topic, both manufacturers and users of such technologies can participate in the project and create a market-oriented focus for the development of future solutions. Examples of possible consortium partners include manufacturers of machines, control systems, sensors, IoT and EDGE devices, AI and cloud solutions as well as end customers who use the aforementioned solutions.

Services

The particular benefit for you as a participant in the project is not only the focused research performance of the Fraunhofer IPA in terms of technology comparison and benchmarking, but also the exchange and contacts between the project partners. All players involved in the process, such as manufacturers, service providers and end customers, are represented here in order to maintain a market-oriented focus. At least four project meetings form the core of the project. Additional workshops and telephone conferences on individual aspects will be held as required during the project. All results of the "AI-ready machining" project are available to the project participants and can be used for their own purposes. Fraunhofer IPA will publicize the project in the press and among its customers through targeted marketing activities.

Overview

AI-ready machining

- Technology comparison of interfaces and protocols

- Benchmark test of selected interfaces and parameters in practical operation

- AI for data preparation and continuous storage of various data

Target group

- Manufacturer of mechanical engineering systems IoT devices and sensors

- Service provider for the integration of cloud and AI solutions

- End users from the industrial environment

Services

- Access to project results

- Interdisciplinary network

- At least four project meetings

- Joint marketing