Food tray automation for clinics

Initial situation

To provide patients in hospitals with individual meals, a wide variety of meals are pre-portioned in the central kitchens of Service GmbH Schwarzwald according to customer requirements and then delivered.

The employees in these central kitchens are subject to increased physical strain due to monotonous tasks. As a result, but also due to demographic change, which is making available capacities increasingly scarce, staff recruitment is becoming more and more difficult. Nevertheless, operational safety and the supply of food to clinics must be guaranteed.

Solution idea

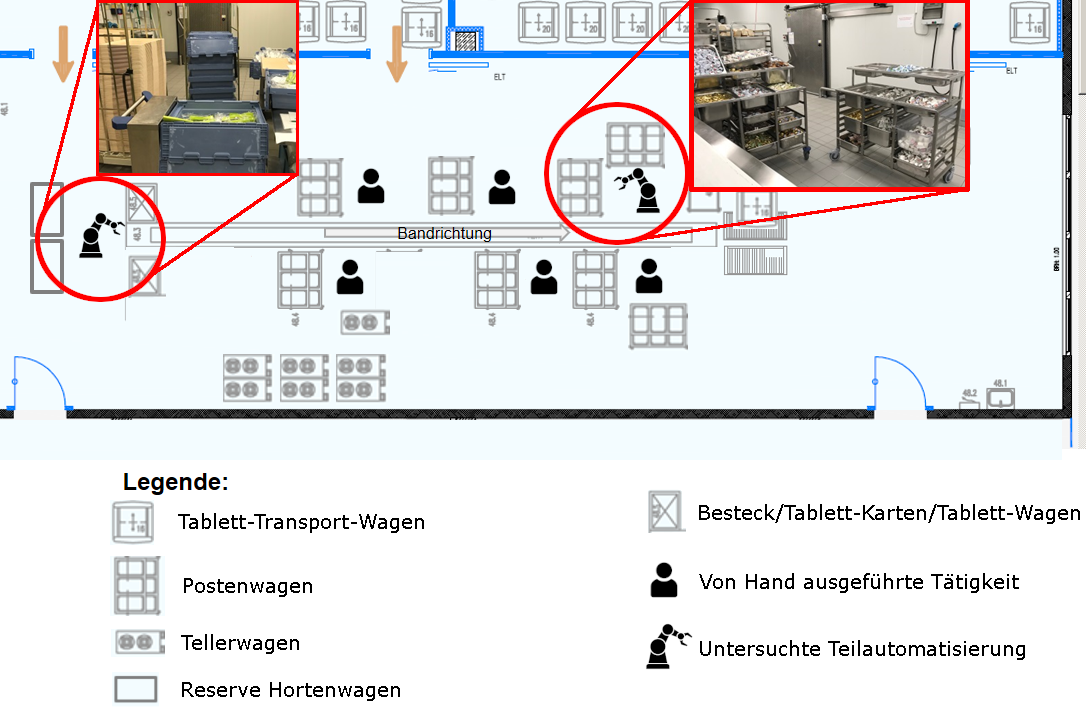

By using robots and AI methods, the portioning of orders is to be partially automated in the future. The food to be put together on a tray is specified by customer orders, automatically localized by the system, picked from the corresponding container and carefully deposited. To enable autonomous execution, methods for object recognition and (model-free) gripping planning are used, based on artificial neural networks. This also enables the robot to adapt dynamically to the speed of its human colleagues.

Benefit

The robot-based composition of meals can ensure that patients are supplied with food, even if no new staff can be employed. Robotic systems offer the advantage of being flexibly adaptable to new tasks or product ranges, which also enables long-term use in other facilities and areas. The robustness of these systems and a lower error rate than with human execution create additional planning security. It can also be assumed that hygiene compliance can be further improved, which creates an additional safety standard for patients.

Implementation of the AI application

The trays are filled with food at several stations. Since the localization and autonomous gripping of the items can vary in difficulty, those with good automation potential were first identified. Using exemplary objects (pre-packed spreads and yoghurt pots), neural networks were then tested for instance segmentation and model-free gripping point determination, which can also be applied to previously unknown objects. A 6-axis robot arm with a suction gripper was thus able to reliably grasp the objects with a success rate of 90% when calculating the gripping point within a few milliseconds.