Instant calculation of CNC components

Initial situation

InstaWerk offers its customers convenient ordering of CNC milled and turned parts via a web platform. The customer uploads the CAD data of their design to a platform and immediately receives a price and can conveniently order the parts online. In order to be able to estimate these in real time, the complexity of the component must be assessed on the basis of the CAD data transmitted. Estimating the complexity is very challenging due to the process-related and component-specific difficulty of the part.

Solution idea

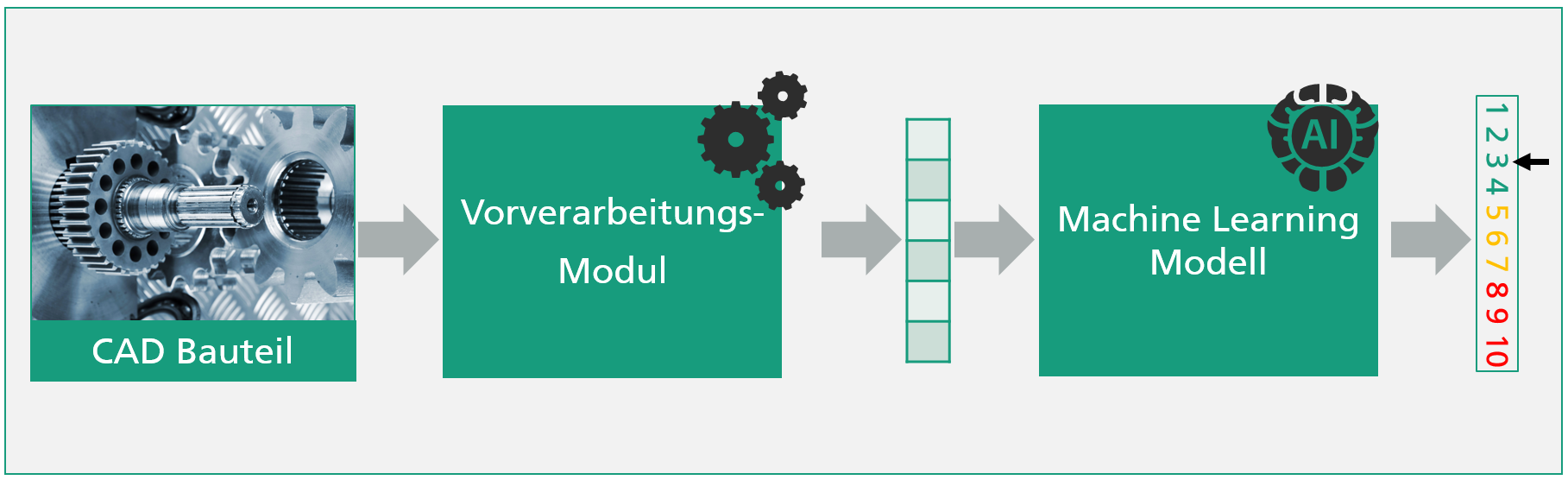

The company already uses pre-processing modules to extract price-relevant features for price calculation on the basis of CNC data. Based on these features, a training data set was generated to form the basis for training a machine learning (ML) model. The aim is to train an ML model in order to reliably estimate the complexity of CNC milled and turned parts.

Benefit

An ML-based approach to complexity estimation enables better cost estimation for the production of CNC components. This reduces manual workload for complexity estimation and time-consuming communication with the customer.

Implementation of the AI application

An initial implementation concept was verified in the quick check. For this purpose, a training data set was created based on existing pre-processing modules for generating features from InstaWerk CAD data. This data was analyzed, pre-processed and used to train various machine learning models for complexity prediction. It was shown that the trained models can be used to reliably estimate the complexity of CNC components with high quality in real time.