Anchor final inspection - quality inspections using AI

Initial situation

When manufacturing armatures for universal motors for power tools, it is essential to carry out a quality inspection after the automated production process. Any damage and manufacturing defects should therefore be detected as early as possible before the armatures are assembled. Quality control is currently carried out by visual inspection by trained specialists, which requires a considerable amount of time and money.

Solution idea

In order to reduce the effort required for manual visual inspection, the aim is to automate quality inspection. One possible innovative approach is to use a camera system to capture the areas of the armature to be inspected and analyze the image data for damage and production defects based on artificial intelligence (AI). As there are many possible manufacturing defects that need to be detected, an AI-based solution offers an efficient and future-oriented alternative to manual visual inspection.

Benefit

A quality inspection with AI contributes to an effective follow-up inspection. If defects are identified automatically and precisely, quality defects and reworking can be reduced. The amount of manual visual inspection by employees is also reduced. This means that personnel costs and therefore production costs can be reduced. In addition, AI-supported inspection offers the possibility of being trained to detect additional types of defects if sufficient data is available. This can make the quality inspection process more flexible and effective.

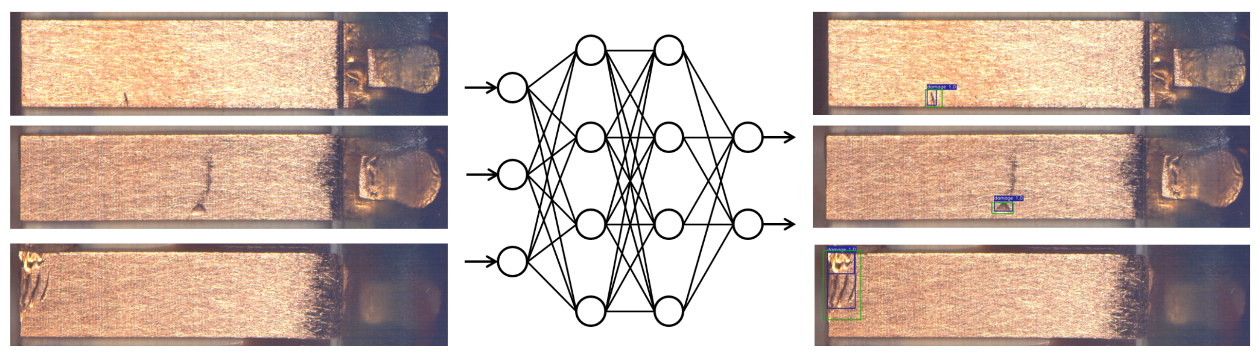

Implementation of the AI application

In an initial investigation, the focus was on detecting surface damage on the collector area of the armature. Images were available that showed the entire surface of the collector. In an initial pre-processing stage, these were separated into images each showing one collector lamella. Images with damage were extracted and annotated. This data set was used to train an AI model for object detection. Due to the small amount of data, a pre-trained network based on the transfer learning approach was used. The model was able to recognize the damage occurring in the test data.