Localization of deep boreholes

Initial situation

In industry, it is common for certain time-, material- and labor-intensive production processes to be automated. In this project, different types of large copper shafts with different hole patterns and hole diameters have to be cleaned with a long tubular tool. To automate this cleaning process, determining the position of the cleaning tool relative to the orthogonal viewing angle of the hole is a crucial step. Later, a robot can be installed that recognizes the position of the hole center, moves the cleaning tool to the center of the hole and performs the rest of the process automatically. A cleaning tool (blowing, brushing, flushing) should be inserted orthogonally in 1000 mm deep holes with a maximum distance of 1 mm from the wall. To achieve such high-precision placement of the cleaning tool, the angle between the cleaning tool and the orthogonal viewing angle of the hole must be calculated with an accuracy requirement of less than 0.057°.

Solution idea

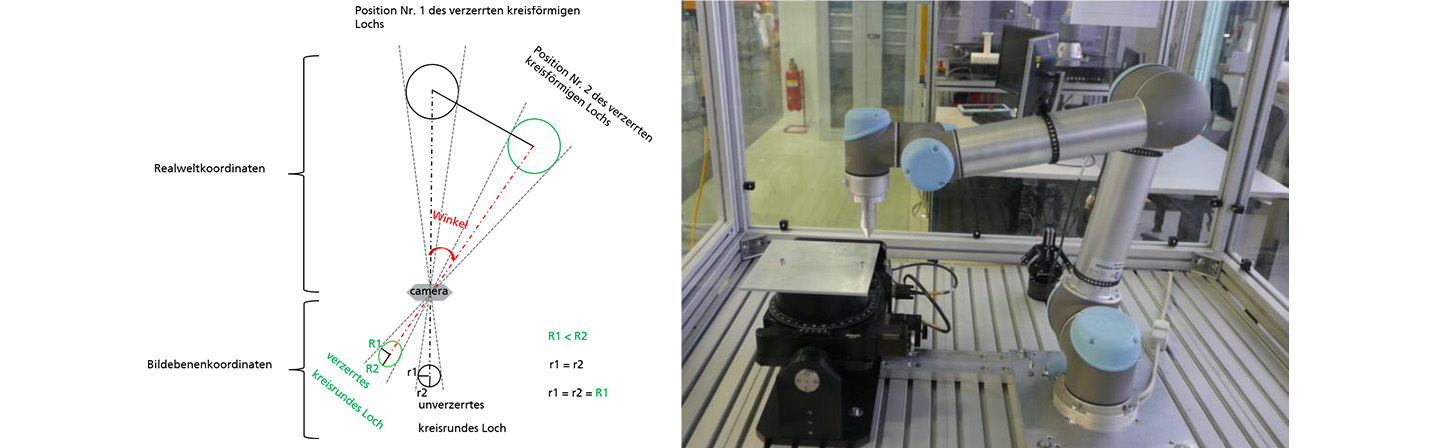

One way of calculating the necessary angle is to use a computer vision method that captures the relationship between the geometry of the hole at different positions and the angle (between the cleaning tool and the orthogonal viewing angle of the hole). In one position, the hole is aligned with the orthogonal viewing angle. The captured image of the hole in this orthogonal position is undistorted. In another position, the hole is tilted in relation to the orthogonal viewing angle. The captured image shows a distorted hole shape, an ellipse instead of a circle. The second option is to scan the face and determine the plane using the measured points and the least squares method. The normal to the plane can then be calculated. This then corresponds to the hole angle.

Benefit

The aim of this project was to investigate automation options. Precise position detection of the components is necessary for automation. Processes for precise position detection are required for a wide range of tasks, such as component handling or component cleaning. Two approaches were examined in the Quick Check and their potential determined. The knowledge gained can also be transferred to other sectors (e.g. textile, wood, construction, recycling or electronics industries).

Implementation of the AI application

A series of tests were carried out in the laboratory to automatically detect the position. Both tactile and optical methods were used for this purpose. Although the desired accuracy of 0.057° could not be achieved, the knowledge gained can be transferred to similar tasks with lower accuracy requirements (>0.6°).