MRK application for equipping machines

Initial situation

Johann Maier manufactures and tests high-strength and corrosion-resistant fasteners of unparalleled quality for the aerospace, oil, international motorsport, defense and security industries. Due to customer-specific designs and small batch sizes, production is largely mechanized, but with little automation in terms of machine loading and logistics. Due to fluctuating demand and a lack of employees, Johann Maier is unable to fully utilize its machinery. Retrofitting the machines with automatic loading by the machine manufacturer is only partially an option due to the age of the machines. Two machine types were identified for the screw forging process for which a human-robot collaboration application for machine loading makes sense.

Solution idea

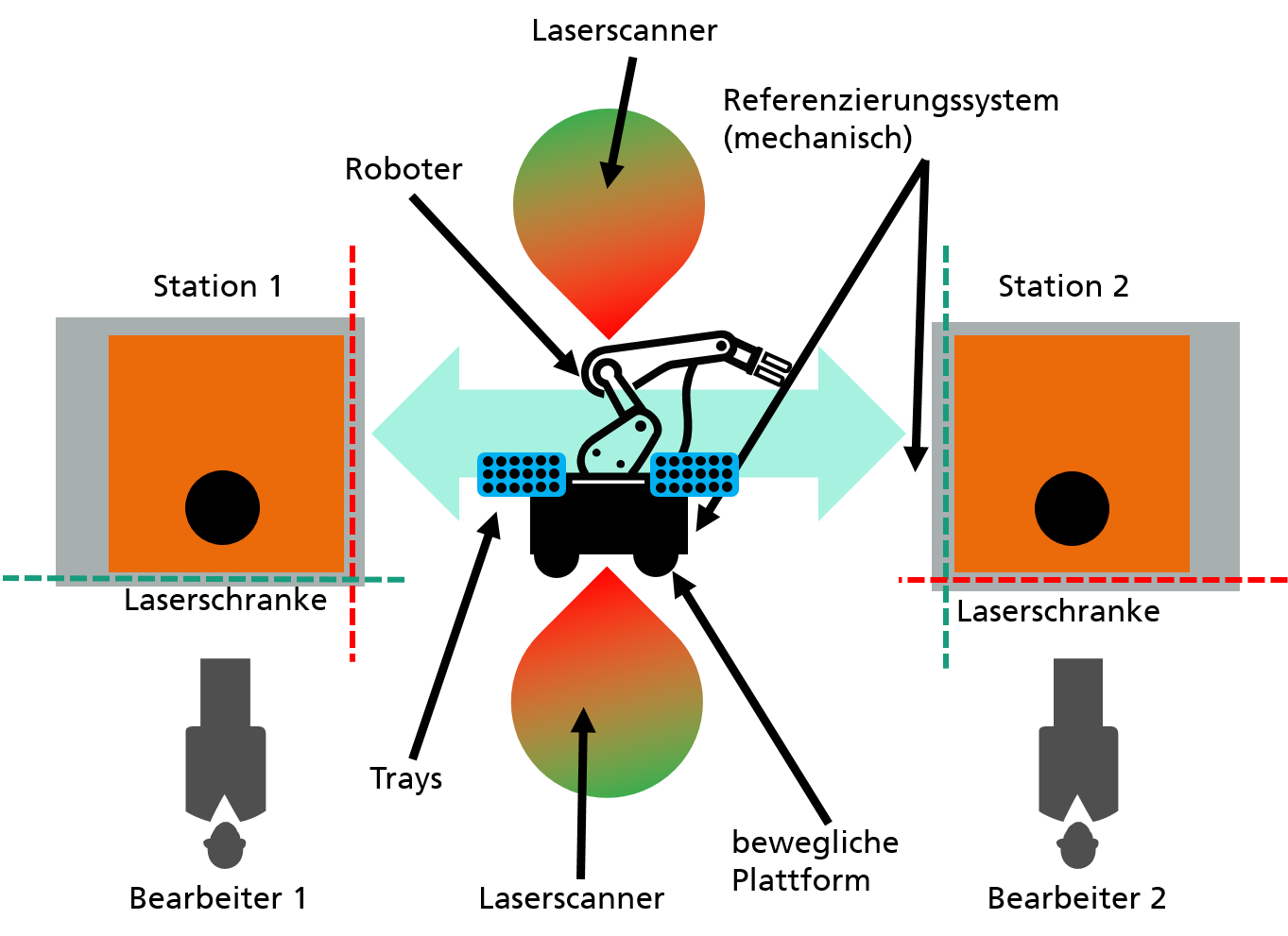

As part of the Quick Check, a concept for equipping the machines for punching screw heads was developed as a collaborative application, which will subsequently serve as the basis for similar applications for other machine types. A robot arm is moved to the station on a mobile base and can then insert the screw blanks into the forging device. The mobile base can be docked to various stations as required or, thanks to its compact design, can also be parked for short periods.

Benefit

The mobile platform serves as a prototype for a collaborative workstation during the forging process of the screw blanks. The support provided by the autonomous loading and greasing of the processing machine and subsequent loading of the screw blanks into a tray allows one operator to work on different processes simultaneously. In addition, the operator is free to operate a second station. The platform can also be used to process orders with larger quantities fully autonomously, which offers potential for additional profit optimization.

Implementation of the AI application

The screw blanks are delivered to the forging process as bulk material in a tray and separated using a bin-picking solution. Here, machine learning methods support the safety and precision of the application, as the bin-picking solution can be adapted to the products. This allows fully autonomous separation of the blanks for additional flexibility in the production process and parallelization of other value-adding processes.