RoboJudge: Successful trial execution with AI

Initial situation

Due to the high number of product variants and tolerances, control cabinet assembly is almost impossible to realize with conventional automation, although the potential is very high. One of the main reasons is the time required for robot programming, which usually exceeds the time required for purely manual assembly. The use of reusable robot skills offers a promising opportunity for automation, also in combination with AI training methods. However, the robot skills cannot determine whether the overall process has been carried out successfully or not, which is why specialized success criteria must be added manually.

Solution idea

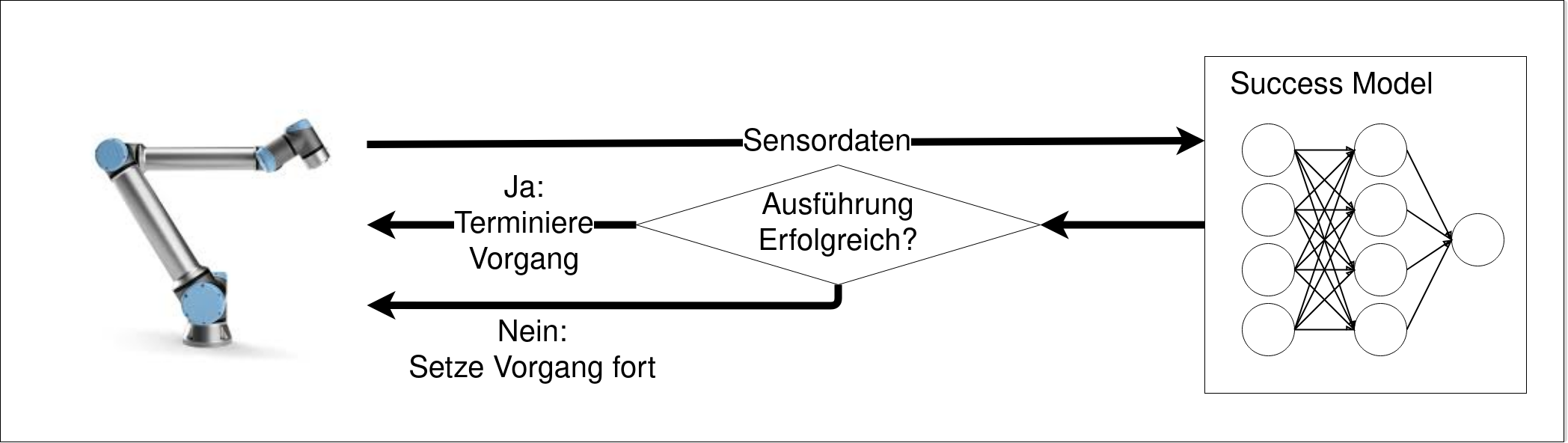

The combination of artificial intelligence methods with advanced simulation tools is being intensively researched, particularly for the programming of flexible assembly processes. During process execution in the simulation, the progress and success of the robot can be closely monitored. The observations are used to train process-specific success criteria using supervised learning. These relate, for example, to the forces that occur during assembly as well as the positions and speeds of the robot and the components. The trained "success models" serve as success criteria in order to continuously record and evaluate the real process.

Benefit

The recording of process progress and success plays an important role in the training of cognitive robots. In order to improve the manually created success criteria or have them generated automatically, "success models" are trained from the simulation to guide the robot in the successful execution of the process. The trained models provide a considerable benefit for the simulative training of assembly processes using artificial intelligence and thus for the goal of automating activities in control cabinet assembly that cannot currently be automated.

Implementation of the AI application

The robot is programmed offline in a powerful, realistic physics simulation. Within the simulation - in contrast to reality - the system status can be fully determined at any time, including the current success of the robot. While the robot is trained in the simulation using "trial and error", the "success model" closely monitors the state of the robot. Depending on its position in space, the forces acting on it and other interactions with the environment, the model determines a success value. This value then indicates whether the robot has reached its goal or not, depending on the observed system status.