Sensor-based adaptation of the welding parameters

Initial situation

Thanks to their quick and easy programming, welding cobots enable the automation of welding tasks, even in high-mix, low-volume production with small batch sizes. The aim of the quick check was to determine the extent to which the sensor information - generated by the newly developed sensor-based programming from Fraunhofer IPA - can be used to adapt welding parameters to the component in question.

Solution idea

The aim of the project was to find a way of adjusting the welding parameters during welding using sensors.

The control computer should automatically adjust the welding parameters for this purpose.

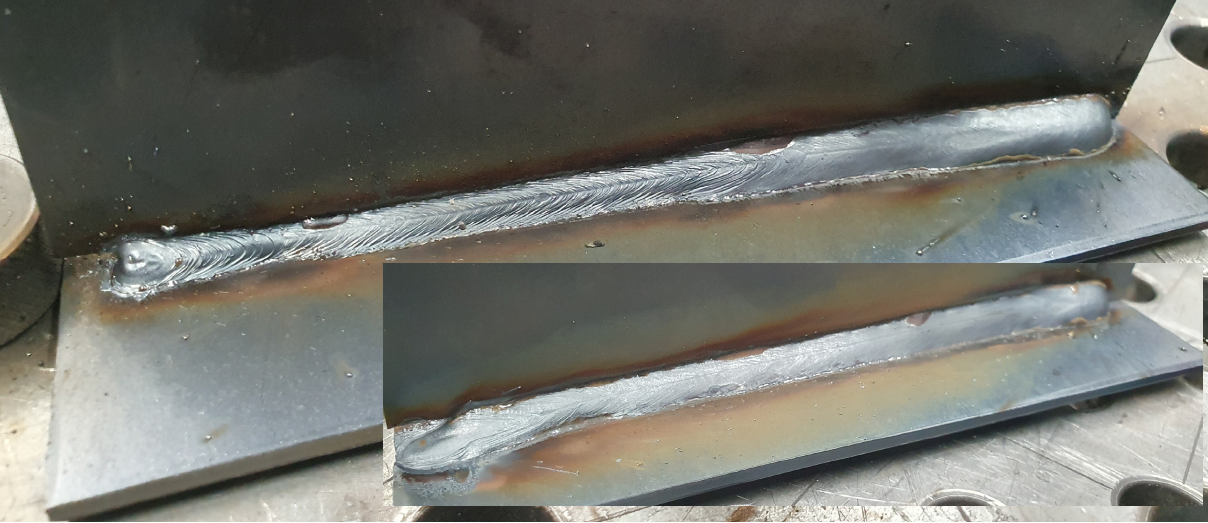

As a result, a workpiece with pure tracking of the contour and associated seam defects and a workpiece with prototypical adaptation of the welding parameters should be produced, ideally with clearly higher weld seam quality.

Benefit

The usability of sensor-based programming is particularly high when classic requirements such as fillet welds and radii can be covered, which cannot be welded in the conventional style due to production inaccuracies such as pipe chamfering. With manual programming, corner runs also require several interpolation points and are therefore complex to program. If sensor-based technology can also be used to program the corner travel of the welding cobot, programming is much easier and faster.

Implementation of the AI application

A specially adapted interface enabled communication between the control computer and the welding source so that the generated target values and the actual values of the welding source could be exchanged. This ensured control and regulation of the welding process by the control computer.