Sensor-based TIG welding of containments

Initial situation

A containment is a double-walled, heatable and coolable container for holding a sterile plastic bag for biotechnology. Various biotechnological processes are carried out in these, such as cell harvesting, purification of active ingredients or the preparation of buffer solutions. Containments are manufactured in different sizes. Depending on the size, the manual welding time is several hours.

Solution idea

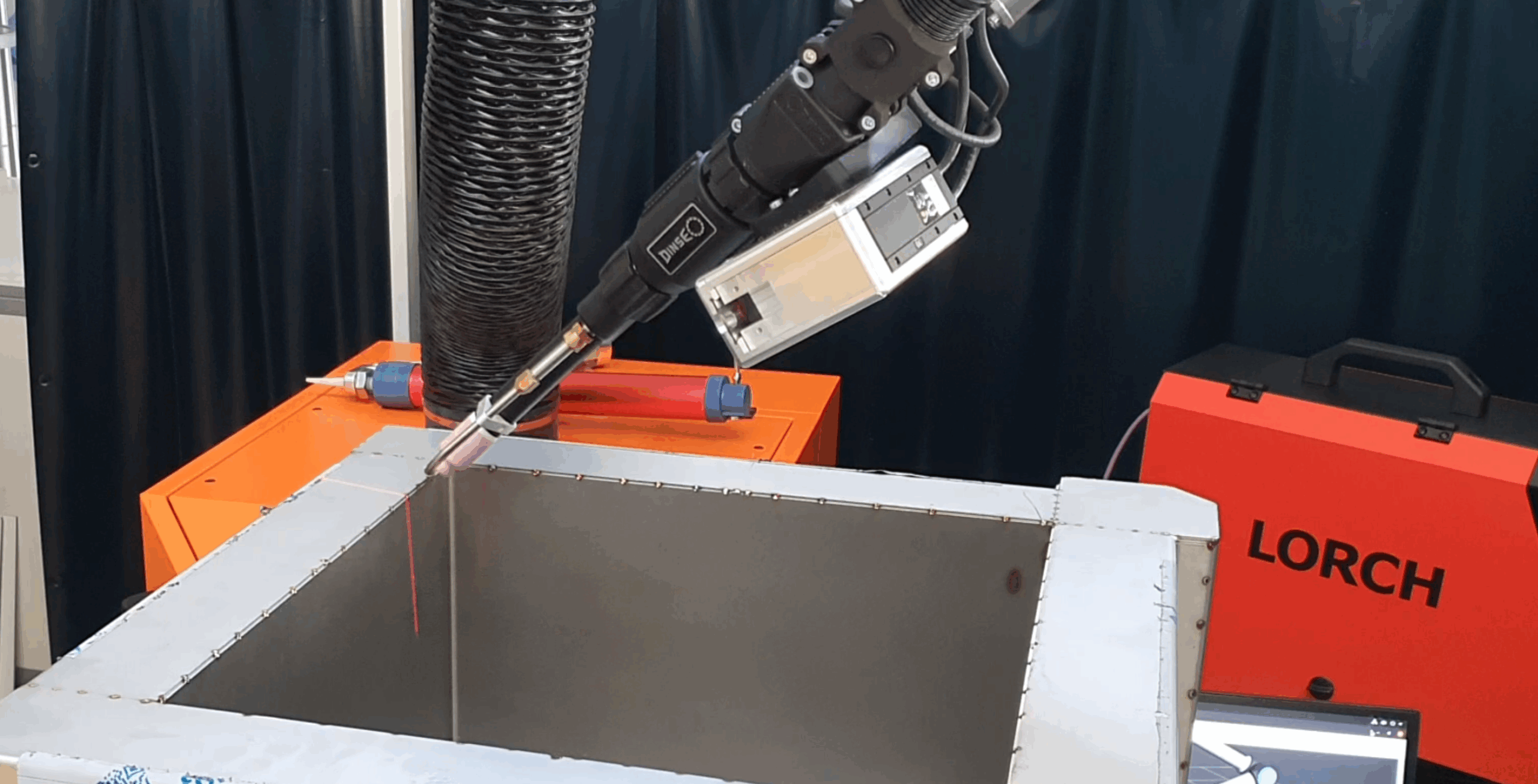

A sensor-guided TIG welding cobot could be used to automate labor-intensive weld seams on the actual containment. For this purpose, a sample containment is to be welded with a TIG welding cobot to show which weld seams are achievable for the cobot.

Benefit

Even if it were possible to weld the 12 vertical and 16 horizontal seams without the corners using a robot, this would reduce costs by around a fifth. In addition, welding the vertical seams is ergonomically very stressful for the employees. If a robot could carry out large parts of the weld seams automatically, this would also significantly reduce this ergonomic strain.

Implementation of the AI application

It was shown that some weld seams can be reached with the robot. The external ones in particular are easy to reach due to the lack of interfering geometries.